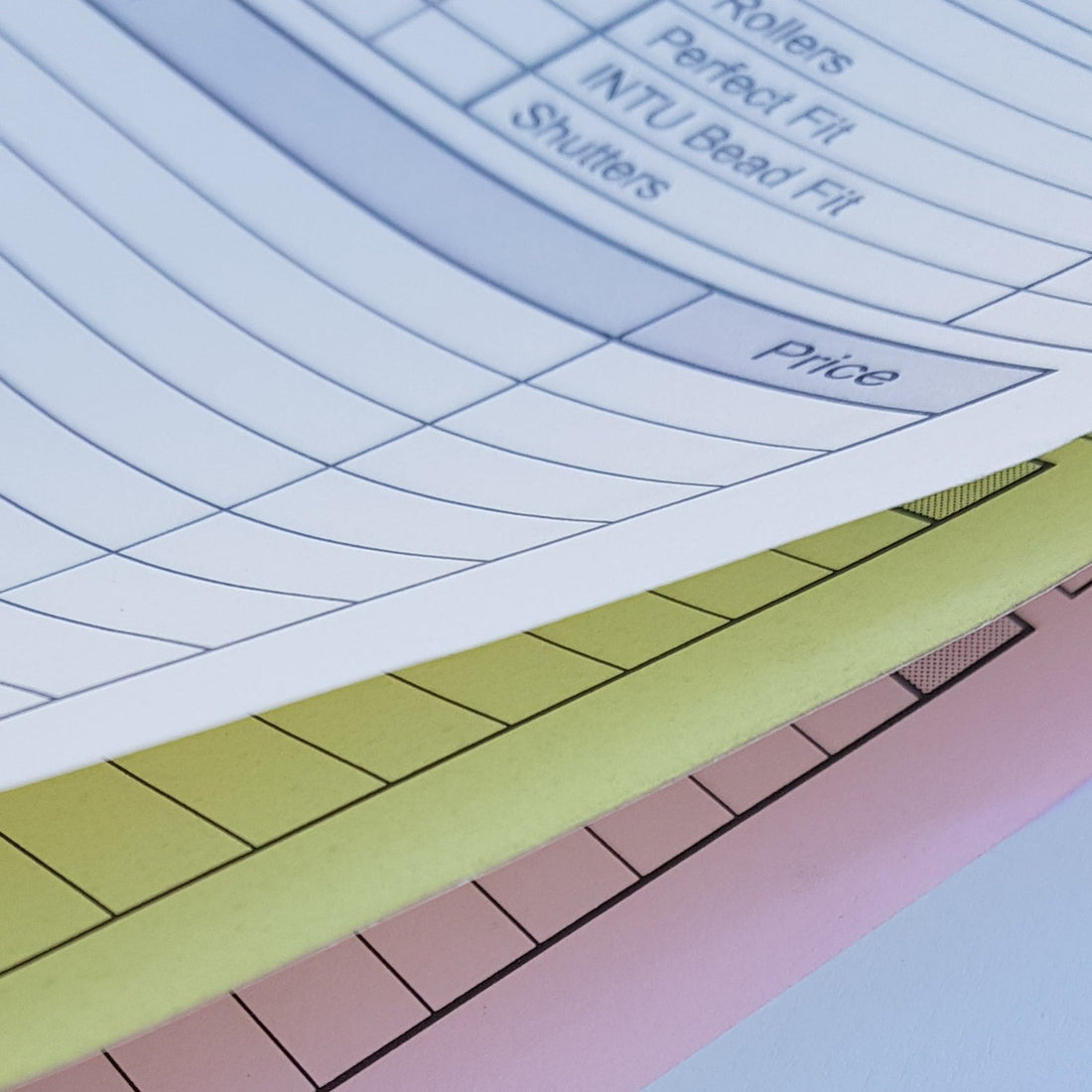

Personalised Invoices, Receipts, Job Sheets, Order Pads, Transfer Forms etc

Share

At MD Print Shop, we specialise in creating high-quality personalised business forms tailored to your exact needs. Whether you're a sole trader, a busy contractor, or a national organisation, we can produce professional carbon copy forms that streamline your business and help you stay organised.

👉 Order NCR Sets (Individual) Now

Click here for a FREE Quote

Call us now: 0191 289 4755

Email: sales@mdprintshop.co.uk

Check our Google 5 star Reviews

📋 Why Personalised Business Forms Matter

Branded forms aren't just about appearance - they're about efficiency, trust, and professionalism. From invoices to delivery notes, having your details clearly printed shows your customers that you mean business.

All our forms can include:

- Your business logo & branding

- Contact details

- Terms & conditions

- Sequential numbering

- Custom layout & format

🧾 Products We Custom Print:

✅ Invoice Pads & Books – For tradespeople, retailers, and service businesses

✅ Receipt Pads – Keep track of every transaction

✅ Job Sheets – Log details of work done and time spent

✅ Order Pads – Perfect for restaurants, takeaways, and wholesalers

✅ Transfer Forms – Essential for stock movement, waste transfers & logistics

✅ Accident & Incident Books – Stay compliant with health & safety requirements

✅ Consignment Notes & Delivery Forms – Keep goods moving with accurate documentation

👉 Order NCR Sets (Individual) Now

🏭 Built to Your Requirements

All forms are printed on carbonless NCR paper in duplicate, triplicate or quadruplicate sets – glued, stapled or perforated to suit your workflow. You can choose from standard sizes like A4, A5, DL, A6, or request a custom format. We even offer sequential numbering, hole punching, and wrap-around covers.

💡 Why Businesses Choose MD Print Shop

- Made to order in the UK (North East based)

- Fast turnaround times & reliable service

- No hidden charges – free delivery to UK mainland

- Expert in-house graphic design support

- Affordable print solutions for every size of business

🛒 Order Online with Ease

Ready to take your business forms to the next level? It’s quick and simple to order online - just choose your product, upload your logo, and we’ll take care of the rest. Need help with artwork or layout? Just let us know!

📦 Order Today & enjoy FREE UK Mainland Delivery on every order.

Click here for a FREE Quote

Call us now: 0191 289 4755

Email: sales@mdprintshop.co.uk

Have you connected with us on Facebook, Twitter, Instagram or Linkedin? You will see all our new products and special offers there.